FOB/CIF Available

ASTM C989 Certified

7-15 Days Lead Time

Free Sample Available - Contact Us Today!

Product

Contact Us

Corundum-Spinel Porous Bricks

- Commodity name: Corundum-Spinel Porous Bricks

- Description

-

Company Profile

Our company currently offers a range of products including Porous Plugs, Seat Bricks, Steel Leakage Prevention Devices, Self-Flowing Castables, Seat Brick Repair Materials, Eco-Friendly Dry Mixes, Magnesia-based Dams, Large Steel Ladle Castables, Draining Sands, Taphole Clays, and Trough Materials. These products span across three major categories: Iron Ladles, Steel Ladles, and Tundishes, encompassing multiple varieties. Additionally, we have integrated some of the industry's leading continuous casting component manufacturers, allowing us to provide customers with comprehensive online services ranging from design solutions, product supply, to construction for Iron Ladles, Steel Ladles, and Tundishes.

Our company houses a permanent technical research and development institute – the Technical Center. The Technical Center regularly organizes technical seminars, where renowned professors from prestigious institutions (including Beijing University of Science and Technology, Zhengzhou University, Wuhan University of Science and Technology, as well as experts from Baosteel) collaborate with our senior technical engineers to discuss and research, providing guidance on product technological development, cooperating in product technical R&D, and recommending outstanding technical personnel to join our company.

We have recently launched a new production line that has significantly enhanced our level of mechanical automation, greatly improving our manufacturing capabilities and quality assurance capacity.

To adapt to the new trends in steelmaking development both domestically and internationally, and to better serve the production of clean steel, our company has introduced a series of new measures to enhance the quality of our porous bricks. These include the integration of nitrides into the original formula, employing the latest international and domestic breakthrough technologies such as the Ceylon and Aron combination, as well as nanotechnology. We are also utilizing diffusive porous technology and embedding plate-style porous technology, ensuring our products maintain a leading edge in performance.

Product Characteristics

The series of porous bricks provided by our company have the following advantages:

1、A wide variety of products with strong specificity, capable of meeting the usage requirements under various smelting conditions.

2、Strong corrosion resistance, with an average erosion rate of less than 0.15mm/min.

3、Effective purging performance, with a high success rate of purging, reaching over 99.8%.

4、Stable product quality, with a fluctuation rate of less than 0.1%.

5、Safe and reliable design structure.

Porous Brick and Seat Brick Forming Workshop

High-Temperature Tunnel Kiln

Arch-Top High-Temperature Shuttle Kiln

Introduction to External Leak-Proof Steel Porous Bricks

Product Structure

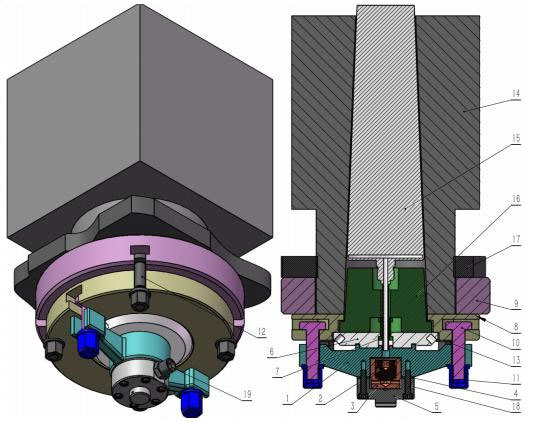

This product is comprised of seven components: the porous brick core, seat brick, support brick, mechanism positioning ring, mechanism positioning plate, steel shim, and the mechanism assembly.

Product Design Principles

⑴ During the use of the product, by tightening the bolts on the positioning plate, the graphite gasket inside the mechanism is compressed and expands, thereby achieving the effect of sealing the gas.

⑵ The inner core of the leak-proof steel mechanism is made of metal copper, which has a high thermal conductivity. In the event of steel leakage from the ladle, when the molten steel comes into contact with the mechanism's inner core, the core melts and instantaneously absorbs a large amount of heat from the steel. This promotes the solidification of the molten steel and blocks the argon blowing holes, thereby preventing steel leakage.

Product Features

⑴The leak-proof steel mechanism features bolted connections, ensuring even stress distribution, simple operation, and a long service life.

⑵ The leak-proof steel mechanism is equipped with triple safety assurances:

Firstly, the porous brick product is designed with a visible core for accurate online determination of the remaining height of the porous brick.

Secondly, the use of a three-layer curved seal can effectively prevent steel leakage between the porous brick and the seat brick, as well as between the seat brick and the bottom of the ladle.

Thirdly, the porous brick is externally connected with a leak-proof wire tube.

The steel mechanism can promptly prevent the molten steel from continuing to leak through the central part. It ensures that no steel leakage accidents occur due to the mechanism itself within its effective lifespan.

⑶ This design approach increases the effective usage height of the porous brick core, thereby enhancing the service life and safety performance of the porous brick core.

⑷ The installation and removal of the mechanism are facilitated by specialized tools, making the operation convenient and straightforward, with low labor intensity.

Quality Assurance Measures

1、Strict control over the quality of raw materials. Each batch of raw materials undergoes chemical and physical testing, including sample testing. For key raw materials, additional phase analysis tests are conducted at external institutes like Luoyang Refractories Research Institute.

2、Regular on-site sampling during production to create test bars for audit inspections. If any anomalies are found, the corresponding batch of products will be treated accordingly.

3、A separate workshop for forming porous bricks and seat bricks has been constructed, achieving relative constant temperature within the workshop and reducing the impact of temperature changes on the forming process.

4、The new high-temperature firing kiln and baking kiln are in excellent condition. The temperature difference inside the firing kiln is controlled within 5 degrees, and the actual temperature difference at various checkpoints in the baking kiln is kept within 10 degrees of the process requirements. This ensures good product stability, with the first-time pass rate of finished products improving by more than 0.5%.

Services Available

1、Provision of a series of porous brick products and related supporting mechanisms, including spare parts.

2、Arrangement of on-site visits and exchanges at other steel plants within our company's client network.

3、Facilitation of consultations and discussions with our company's external academic experts on technical issues for clients.

4、Regular telephone or visitation services to monitor product usage.

5、Implementation of one-to-one service, with personnel permanently stationed in the market to ensure timely feedback on various tasks.

Service Commitment

1、Guaranteed quality and quantity of products.

2、 Professional technical personnel to provide on-site service at least once a quarter, for no less than 10 days each time.

3、In the event of product quality incidents, dedicated personnel will be dispatched to the site within 24 hours for follow-up handling.

4、Response time for other demands during product provision not exceeding 5 working days.

Keywords:

Ready to experience Z-LINK ECO Mineral?

Click to view company profile